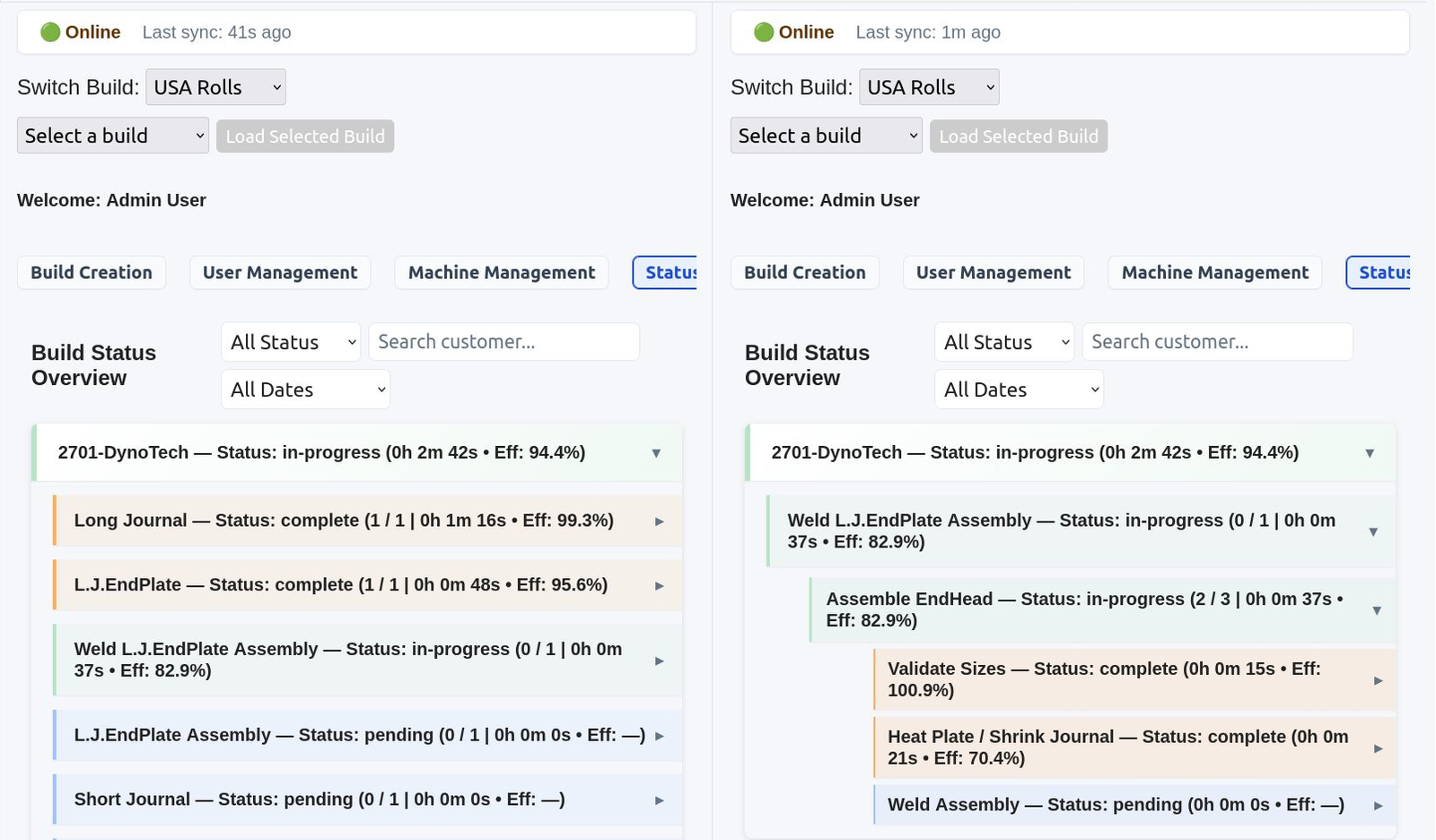

Complete Production Visibility

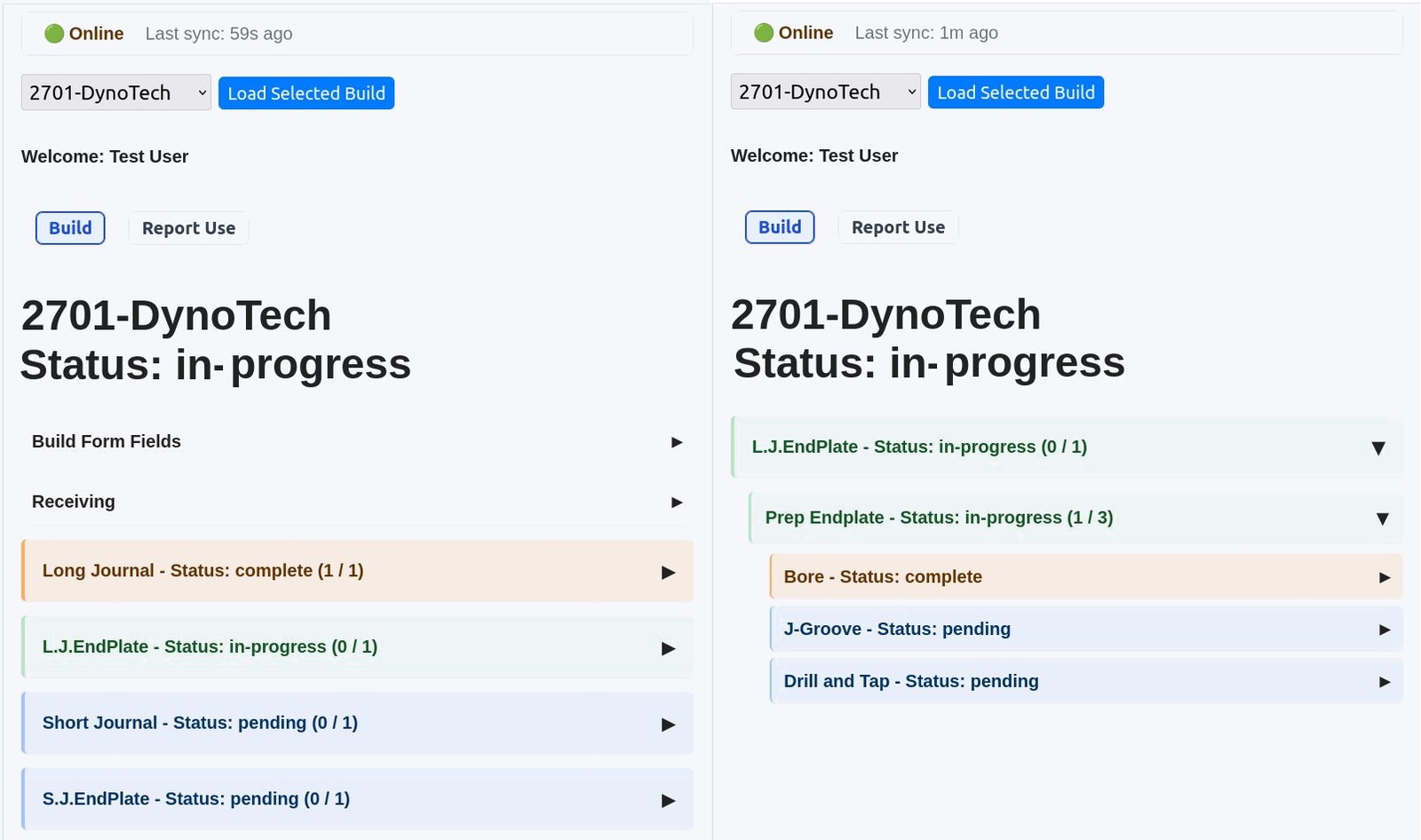

We see every detail of production in real-time

See how our advanced internal systems deliver superior results for your projects

Real-time visibility translates to better quality, faster delivery, and lower costs. Take a look inside our manufacturing intelligence platform and discover the USA Rolls advantage.

We see every detail of production in real-time

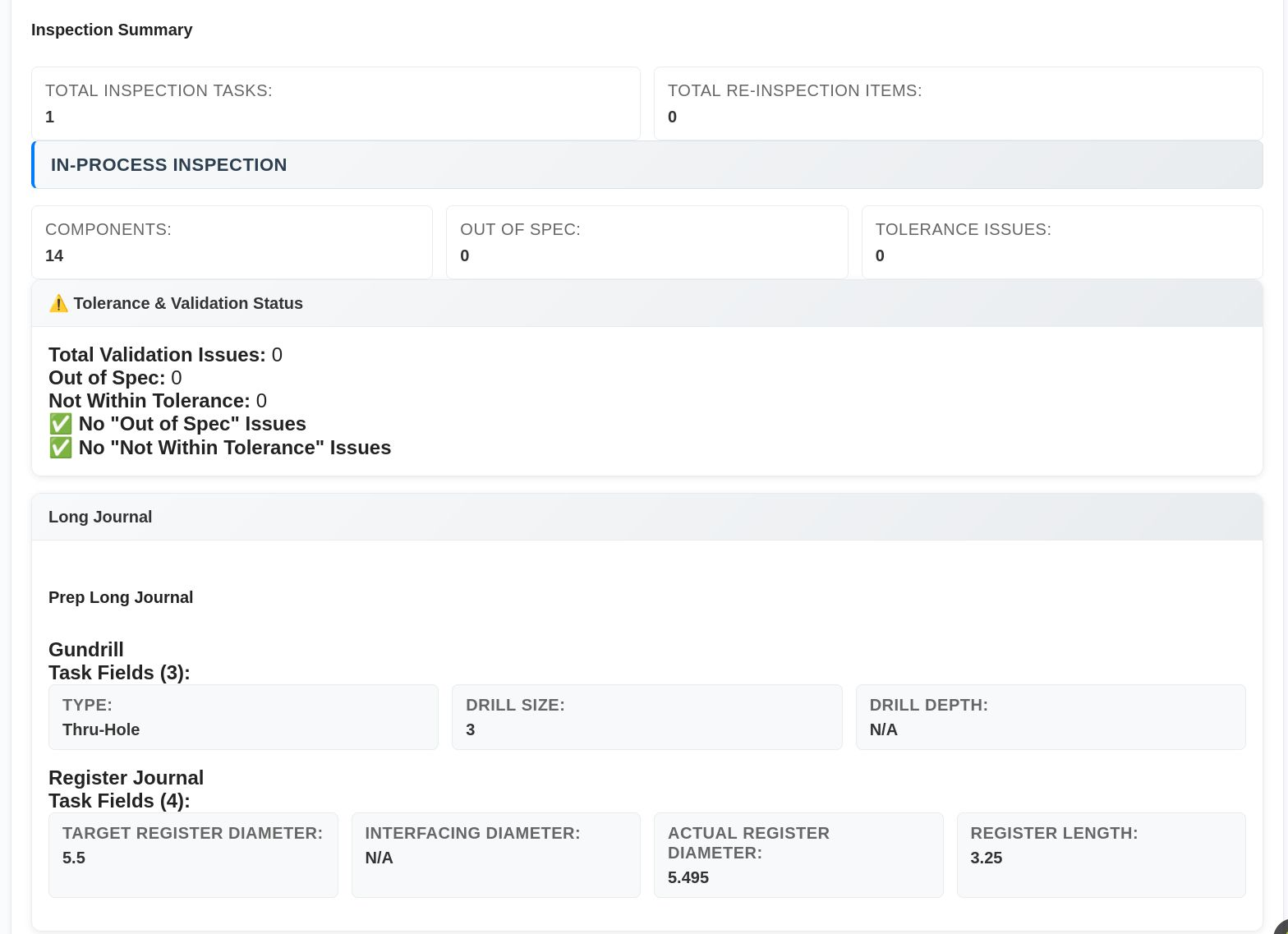

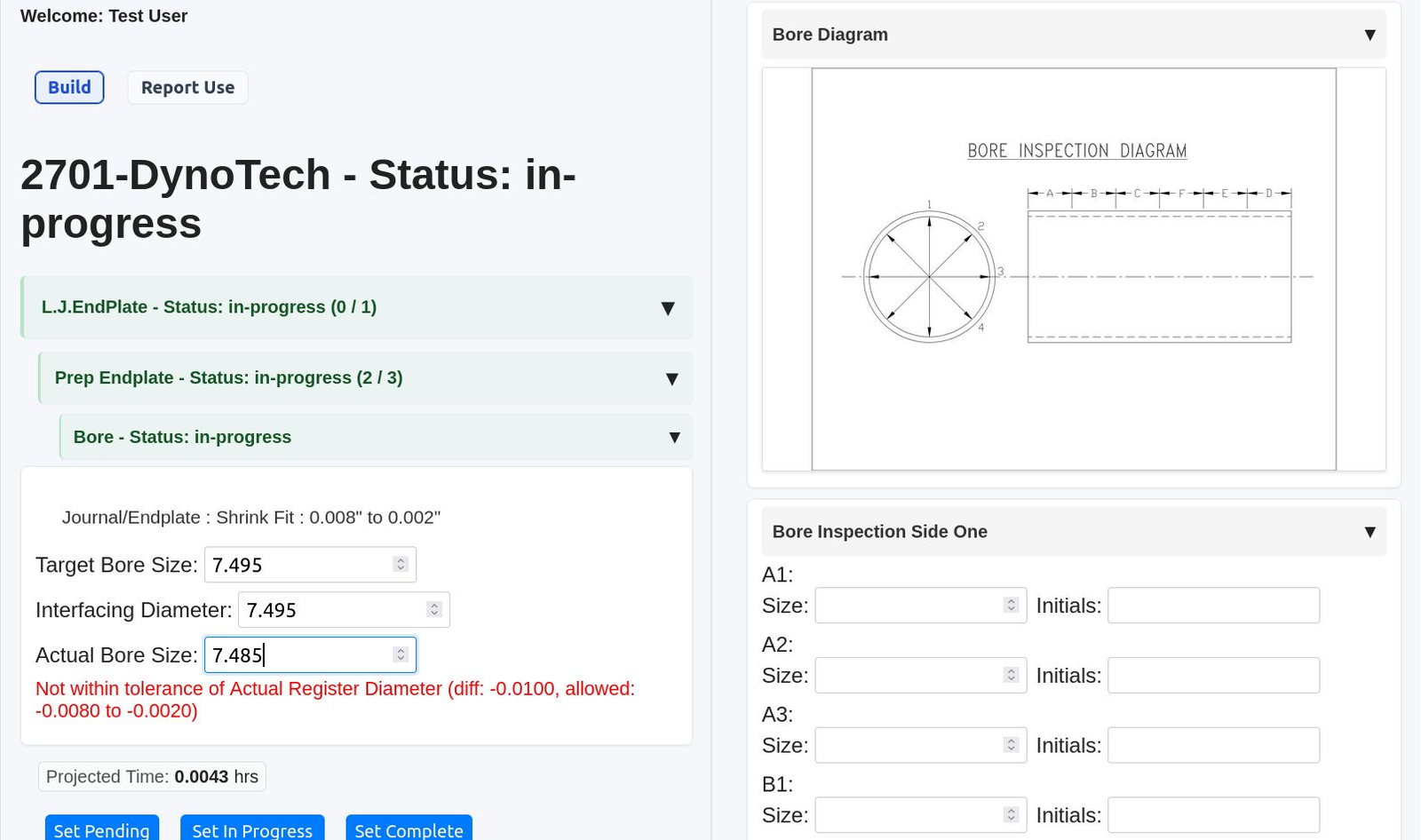

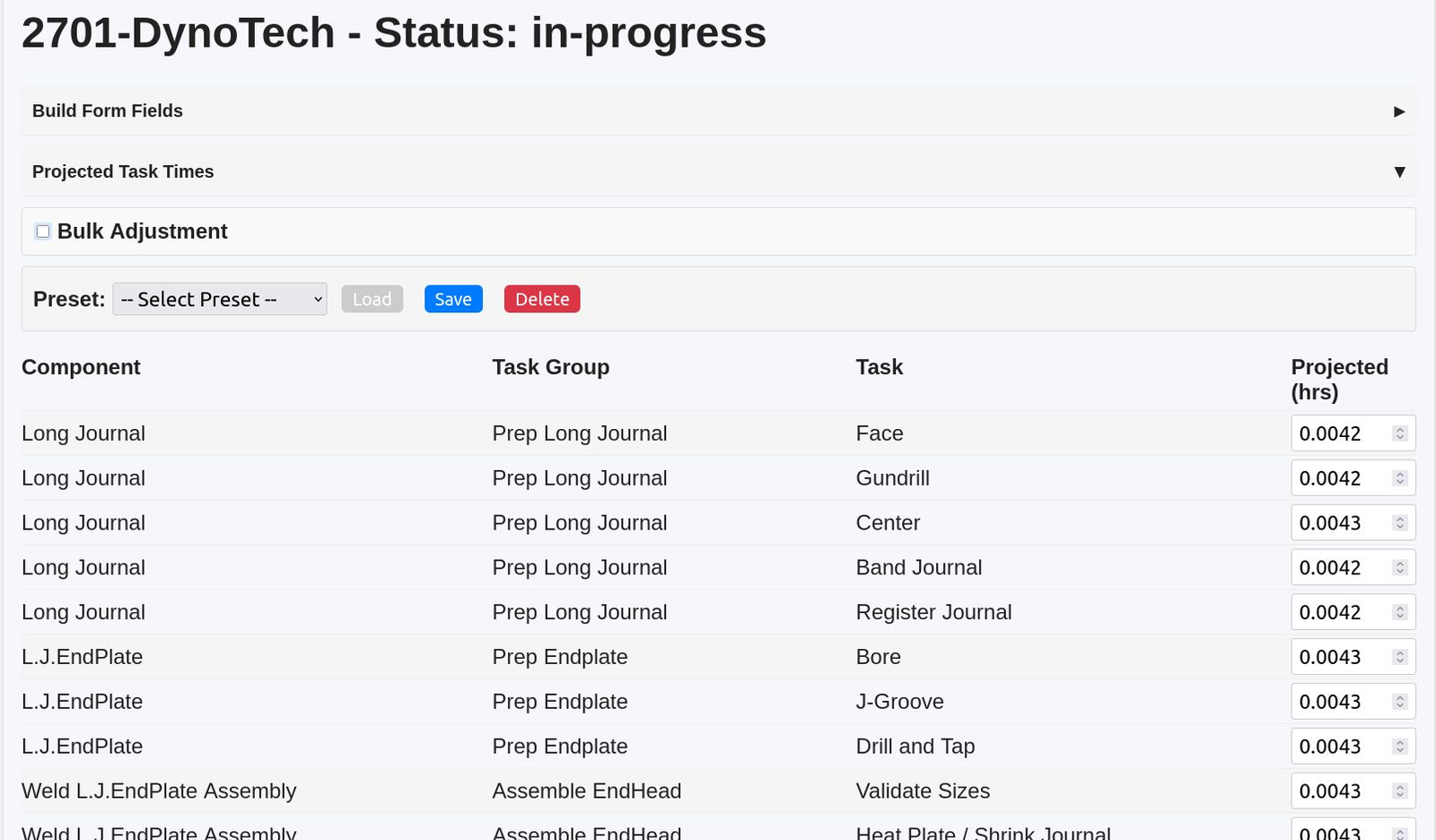

Every critical dimension tracked and verified

We identify and eliminate production slowdowns immediately

We track every piece of material and consumable used

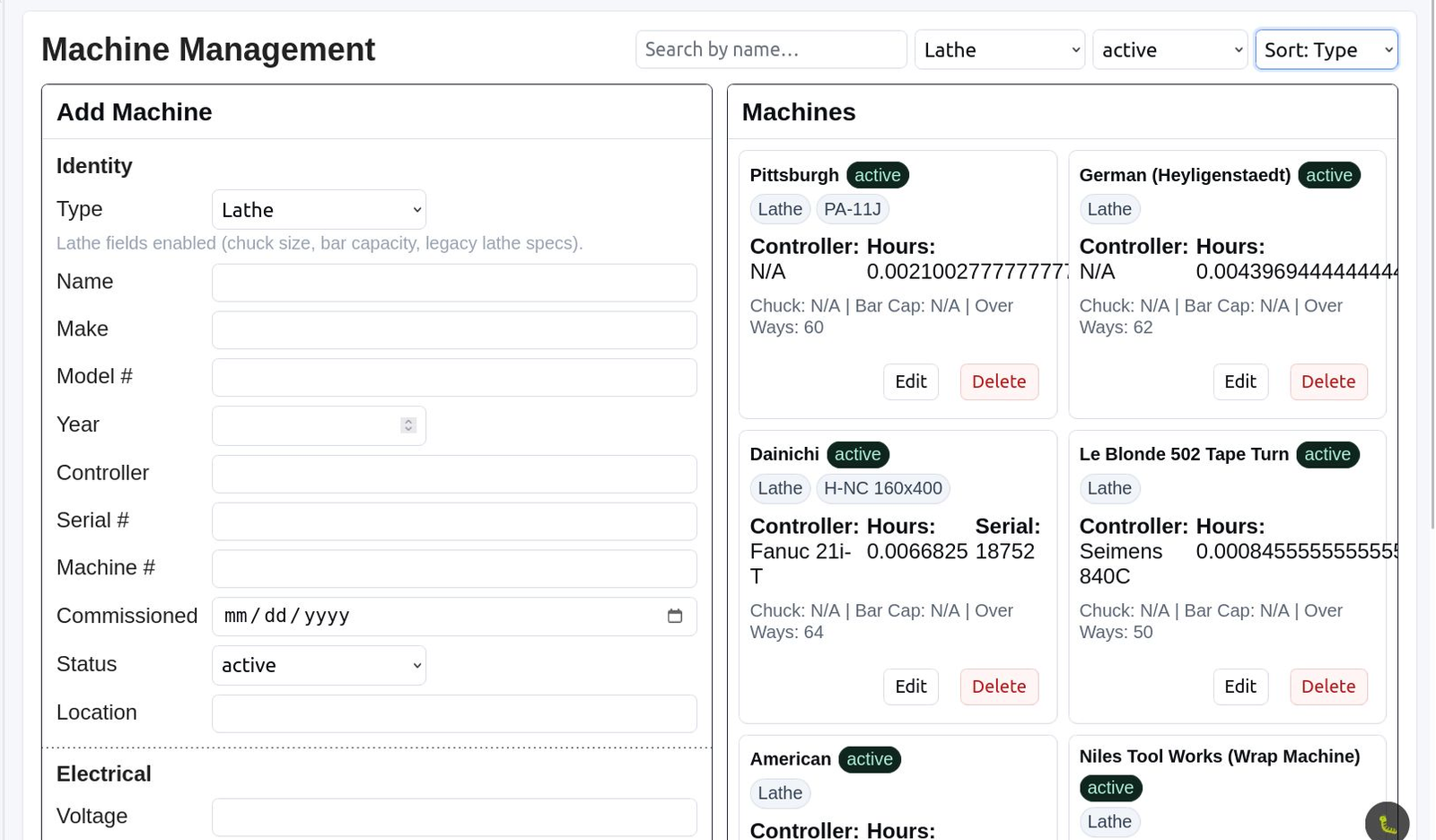

Every machine optimized, maintained, and ready

We know exactly how long each operation takes

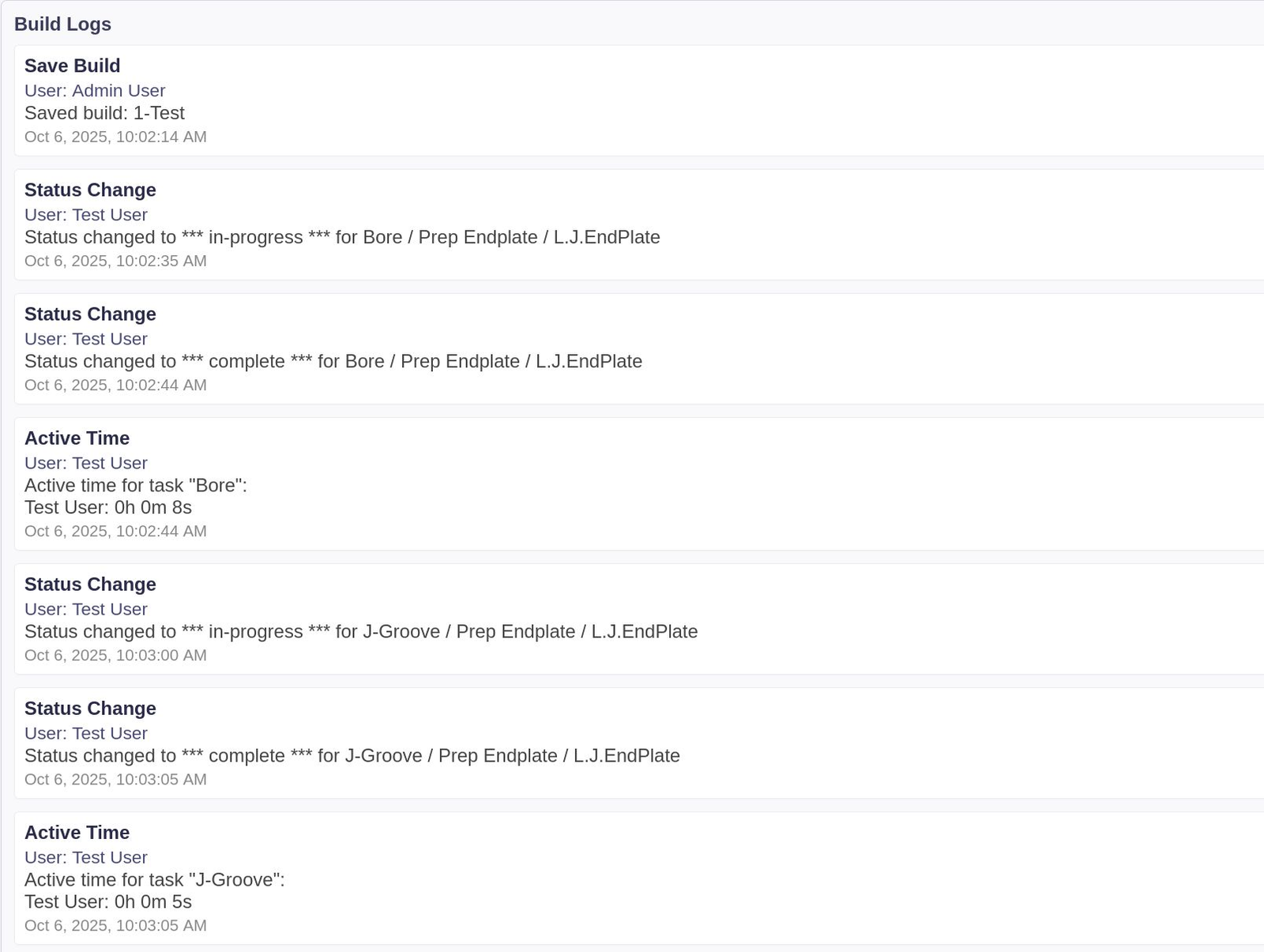

We don't just track data—we learn from it

Full traceability from start to finish

Data-driven decisions at every level